Time to tear it down.

Warning, some viewers may find these images disturbing, viewer discretion is advised.

Cylinder 3

Chatter marks at 11:00

Piece of ring embedded into the ring groove

Molten aluminum and polishing the broken ring.

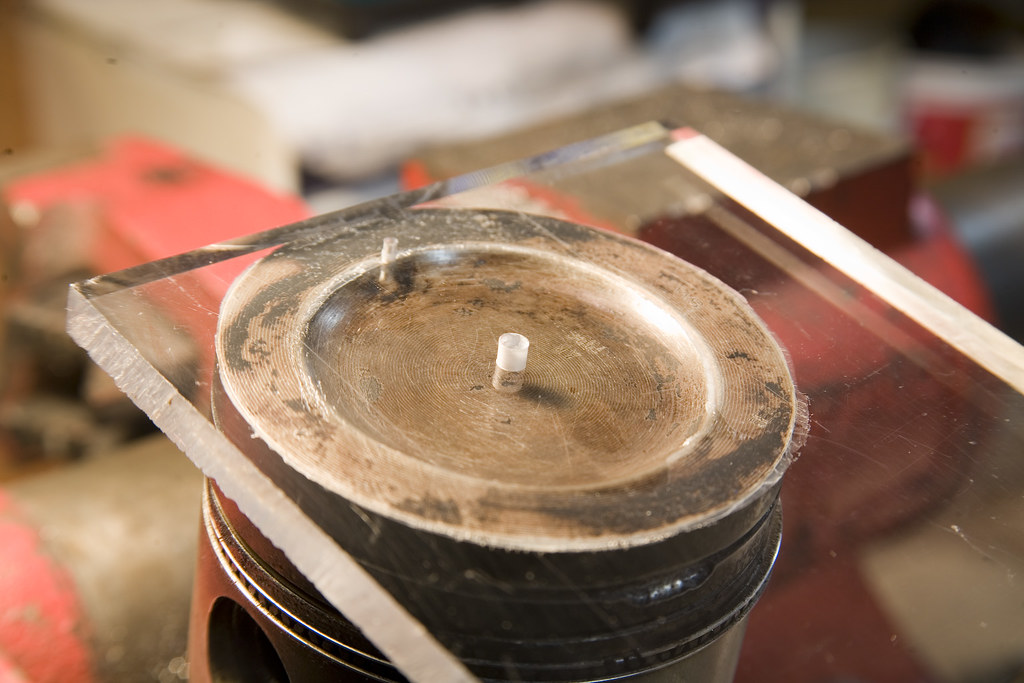

Cylinder 4

Broken ring and melted piston. Which came first?

Cylinder 2

Notice above the top ring the skirt's machine marks have melted to a pitted surface.

My friend Brian who in an engine development engineer had this to share after reviewing the images.

"Looking more closely at the pictures, I'm guessing the top rings are cast iron instead of steel. Also examining the land pictures more closely, it appears the land did not fail in bending, rather the ring broke. This would be expected with cast rings in an application with high peak cylinder pressure. The proximal cause would be fatigue failure due to the ring twisting (toroidally). Steel is much more fatigue resistant, and would be prescribed for the top ring in a heavily pressure charged application or one where heavy detonation is a possibility.

Once the ring breaks, nothing good happens after that. If a piece small enough breaks off, it gets jammed between the groove or land and the bore. This is probably what beat out the 2nd land on piston 3 and scuffed bores 3 and 4. The seal of the top ring is defeated and overall blow-by through the ring pack goes up. Combined with the gouge in piston 4's top land and the scuffed bore, this torches the lands and overheats the crown. That leads to the crown out-growing the bore and mechanical interference between the top land and the bore.

I think piston 2 looks like it was simply overheated or overstrained because I'm not aware of any damage to the rings. That leads to the same land-bore interference seen on piston 4. Note that due to mechanical and thermal stresses, the crown typically distorts to a mushroom shape, and both the top and the second lands tilt down. This would explain why the top of the top land is scuffed and the top of the 2nd land is worn.

If only one piston showed signs of overheating or overpressuring, I'd say to look for a localized detonation problem. But, knowing that this is a highly boosted engine and mention was made of loss of cooling system control, my concern would be overall piston temperature and peak cylinder pressure. Beyond repairing and replacing the damaged parts, my recommendations would be as follows:

1) Switch to a steel top ring.

2) Re-examine the engine after some hard runs to see if there still exists land-bore contact even without overheating.

If there is still contact, the piston design might need to change. The brute force fix would be to increase land-bore clearance of the top land until the contact goes away. This could be done with sandpaper on a lathe. Note that hard tooling will not work due to the likely nonzero ovality of the land. We can talk about details if this step is required.

I have some other ideas beyond manipulating piston-bore clearance, but let's see if the problem persists once you get a durable ring in there and run it hard again.

-Brian"

More to come.

Dennis

.

.