16 valve B motor - living the dream

Re: 16 valve B motor - living the dream

And the completed larger pulley, something is finished!

- DrewP

- Posts: 2084

- Joined: Wed Dec 26, 2007 8:27 pm

- Nickname: TANK

- Number of Saabs currently owned: 1

- Location: Monrovia, CA

Re: 16 valve B motor - living the dream

I'm here! Remembering my glory days when I could get into the prototyping shop to go chip farming whenever I wanted!

I've been shopping machines lately and am biding my time till a decent Hardinge HC / TFB / HLV shows up for sale, I'll make space for that.

What make is your lathe, and how do you like it? I can never really tell from your photos what you have (the B-port is obvious, thank goodness.) I don't really want to buy an aging gap bed in case I want to make anything that needs to hold a tolerance, like for press fits - which I'm sure I will want to as soon as I break down and buy a shitty machine just cause it's $800 and comes with tooling... 8(

EDIT: I do have a question for you, more of a nit-pick actually. From the shot of the pulley on your rotary table when you were hogging the groove out, did you plunge it down and cut full depth with that 2-flute ball for every pass?

Since balls don't like to plunge I was going to suggest cutting a narrow square sided groove at the CL of the groove with like a 1/4" 2-flute that you could shop out in a hurry so you didn't have the centrepoint of the 2-flute ball be what was limiting your feed, how deep were you plunging per pass? I'd be surprised if I'd want to go deeper than like 0.050" on a knee roughing machine in AL, just so I didn't gum up the tip of a big ball-end like that. You could cut 0.150 easy if the center channel was cut down to a little shy of full depth beforehand.

Sort of like pilot drilling a hole.

Drew

I've been shopping machines lately and am biding my time till a decent Hardinge HC / TFB / HLV shows up for sale, I'll make space for that.

What make is your lathe, and how do you like it? I can never really tell from your photos what you have (the B-port is obvious, thank goodness.) I don't really want to buy an aging gap bed in case I want to make anything that needs to hold a tolerance, like for press fits - which I'm sure I will want to as soon as I break down and buy a shitty machine just cause it's $800 and comes with tooling... 8(

EDIT: I do have a question for you, more of a nit-pick actually. From the shot of the pulley on your rotary table when you were hogging the groove out, did you plunge it down and cut full depth with that 2-flute ball for every pass?

Since balls don't like to plunge I was going to suggest cutting a narrow square sided groove at the CL of the groove with like a 1/4" 2-flute that you could shop out in a hurry so you didn't have the centrepoint of the 2-flute ball be what was limiting your feed, how deep were you plunging per pass? I'd be surprised if I'd want to go deeper than like 0.050" on a knee roughing machine in AL, just so I didn't gum up the tip of a big ball-end like that. You could cut 0.150 easy if the center channel was cut down to a little shy of full depth beforehand.

Sort of like pilot drilling a hole.

Drew

Last edited by DrewP on Mon Dec 13, 2010 4:12 pm, edited 1 time in total.

"You can educate ignorance, but you can't fix stupid."

-

KPAero

- Posts: 409

- Joined: Thu Feb 11, 2010 6:42 pm

- Nickname: Pascal

- Number of Saabs currently owned: 2

- Location: Ipswich, MA

Re: 16 valve B motor - living the dream

Luke wrote:I feel a bit like I may be talking to myself this is week, but here some more pics incase somebodys out there!

This project is really cool. Keep the pics coming! What are your plans for the motor? Do you think you might use it in one of the rally cars?

- Crazyswede

- Team Turbo Troll Crew

- Posts: 4540

- Joined: Fri Sep 22, 2006 3:53 pm

- Nickname: Mongo

- Number of Saabs currently owned: 97

- Location: Vermont

- Contact:

Re: 16 valve B motor - living the dream

KPAero wrote:Luke wrote:I feel a bit like I may be talking to myself this is week, but here some more pics incase somebodys out there!

This project is really cool. Keep the pics coming! What are your plans for the motor? Do you think you might use it in one of the rally cars?

The plan the Luke doesn't know about is to run the car in Boucles de Spa 2012. We just have to convince Stig and Per to back us on this because it is a damn near replica to the car that Saab built and won the event with.

I am the 73%

Re: 16 valve B motor - living the dream

KPAero wrote:Luke wrote:I feel a bit like I may be talking to myself this is week, but here some more pics incase somebodys out there!

This project is really cool. Keep the pics coming! What are your plans for the motor? Do you think you might use it in one of the rally cars?

The engine will hopefully go into my 75 silver/green ems shell. Its more or less complete just awaiting a drivetrain.

Re: 16 valve B motor - living the dream

DrewP wrote:I've been shopping machines lately and am biding my time till a decent Hardinge HC / TFB / HLV shows up for sale, I'll make space for that.

What make is your lathe, and how do you like it? I can never really tell from your photos what you have (the B-port is obvious, thank goodness.) I don't really want to buy an aging gap bed in case I want to make anything that needs to hold a tolerance, like for press fits - which I'm sure I will want to as soon as I break down and buy a shitty machine just cause it's $800 and comes with tooling... 8(

Since balls don't like to plunge I was going to suggest cutting a narrow square sided groove at the CL of the groove with like a 1/4" 2-flute that you could shop out in a hurry so you didn't have the centrepoint of the 2-flute ball be what was limiting your feed, how deep were you plunging per pass? I'd be surprised if I'd want to go deeper than like 0.050" on a knee roughing machine in AL, just so I didn't gum up the tip of a big ball-end like that. You could cut 0.150 easy if the center channel was cut down to a little shy of full depth beforehand.

Drew

Hey Drew thanks for the tip on the ball end, yes they suck at plunging for sure. I didnt have too much trouble though, I think I was taking about an .090 cut or so, but if I need to take a deep cut again I'll keep that in mind, I just kept going round and round and I was there in no time.

The Lathe is a Kerry AG. It was made in England, about 1955 or so, not many of them in this country. Super stout constructon. When I sold my harbor freight lathe/mill combo I was looking for a nice southbend heavy 10, or ( if I could find one under 2K) a maximat V10 or super 11. But the Kerry showed up on craigslist, I haggled and picked it up for $250! It was in very nice shape but the threading gearbox was toasted and the lead screw was missing. I sourced some gears and a lead screw and cleaned it up and its been great, so much better than a south bend and honestly a lot more heavy duty than a maximat. Flame hardened bed, full gearbox and x and y auto feed that are selected from the carriage and driven off a separate lead screw- it was a decked out lathe for its time. The only thing that sorta sucks its is a small spindle bore version with a 4 MT taper in the headstock- so I cant quite run 5C collets, I have a nose piece for 2A collets (up to 7/8" IIRC) and a set of 4MT collets, but those are internal thread so depth limited of course.

A Hardinge HLV was out of my league at the time, but the prices do keep dropping.... and theres no doubt that using one is orgasmic.

- DrewP

- Posts: 2084

- Joined: Wed Dec 26, 2007 8:27 pm

- Nickname: TANK

- Number of Saabs currently owned: 1

- Location: Monrovia, CA

Re: 16 valve B motor - living the dream

That's what I thought too, but there's a nearly local guy selling a tooled out HLV for something like $4500 with complete set of 5C's, 3 and 4-jaws, steadyrest and followers, all kinds of shit.

And the other day there was like an '80 HLV with no tooling for like $2k....

We had all ex-Navy Hardinge tooling lathes in the school shop, like 6 of them! And even the ones with ways shot to shit from never being lubricated and all full of foam shavings cut dead nuts of you were steady on the finish pass.

People trying to offload out here lately - I'm doing good convincing myself not to run out and buy a Southbend - there are tons out here that must be leftovers from LA Unified shop classes that shut down 10+ years ago, lots of Logan machines too.

We'll see....

That Kerry looks great, looks like a nice layout for something to stand in front of and everything falls to hand.

Looks like you got a pretty solid setup though, finish on that pulley looks great, and you didn't have to go that deep anyway. The setup is the killer on single-part runs anyway, not the table time anyhow.

What's up next?? <--- [this would be a smiley drooling on itself if there was one I could use, but alas, 'Hungry for More' will have to do...]

<--- [this would be a smiley drooling on itself if there was one I could use, but alas, 'Hungry for More' will have to do...]

And the other day there was like an '80 HLV with no tooling for like $2k....

We had all ex-Navy Hardinge tooling lathes in the school shop, like 6 of them! And even the ones with ways shot to shit from never being lubricated and all full of foam shavings cut dead nuts of you were steady on the finish pass.

People trying to offload out here lately - I'm doing good convincing myself not to run out and buy a Southbend - there are tons out here that must be leftovers from LA Unified shop classes that shut down 10+ years ago, lots of Logan machines too.

We'll see....

That Kerry looks great, looks like a nice layout for something to stand in front of and everything falls to hand.

Looks like you got a pretty solid setup though, finish on that pulley looks great, and you didn't have to go that deep anyway. The setup is the killer on single-part runs anyway, not the table time anyhow.

What's up next??

<--- [this would be a smiley drooling on itself if there was one I could use, but alas, 'Hungry for More' will have to do...]

<--- [this would be a smiley drooling on itself if there was one I could use, but alas, 'Hungry for More' will have to do...]"You can educate ignorance, but you can't fix stupid."

Re: 16 valve B motor - living the dream

DrewP wrote:What's up next??<--- [this would be a smiley drooling on itself if there was one I could use, but alas, 'Hungry for More' will have to do...]

Oh I forgot to mention, another lathe I was looking for was a harrison M250, they had one at RIT and it was really nice, they were used a lot in college shops and are a perfect size for the home shop and nearly tool room quality, but they don't come up for sale too often.

Next up I need to build a coolant distribution manifold, an air/oil separator, the timing cover, and modify the jackshaft for better oiling.

- Geoff

- Team Turbo Troll Crew

- Posts: 3890

- Joined: Fri Oct 20, 2006 3:31 pm

- Nickname: Geoff

- Number of Saabs currently owned: 6

- Location: Nude Humpshire

Re: 16 valve B motor - living the dream

Looks awesome! Do you ever go to work?

The kind of dirty that doesn't wash off

Re: 16 valve B motor - living the dream

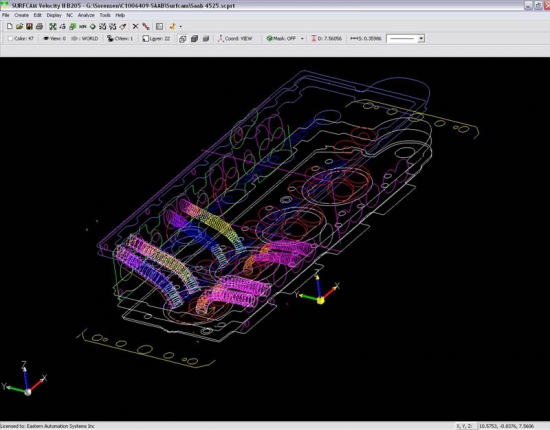

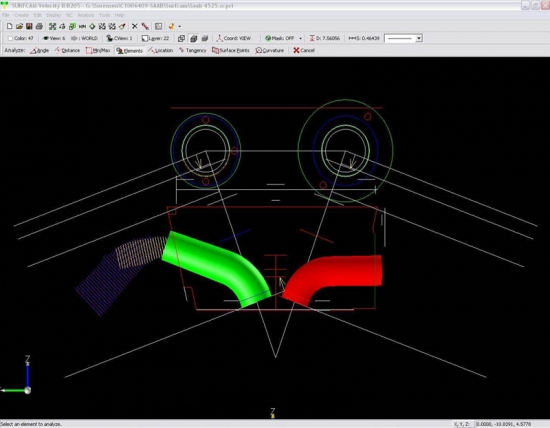

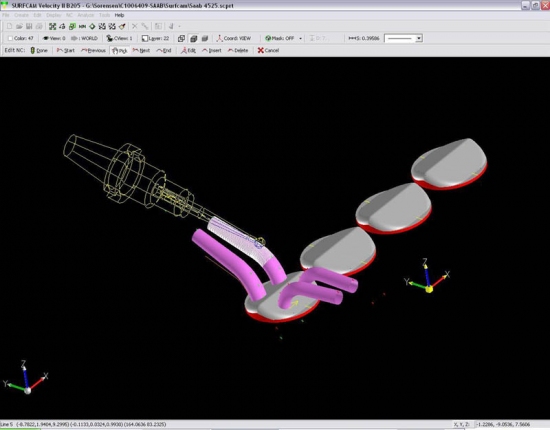

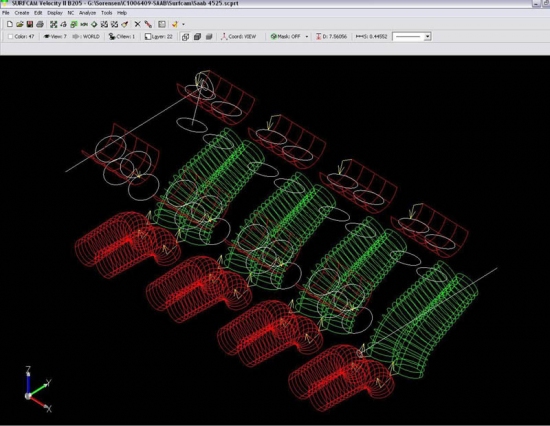

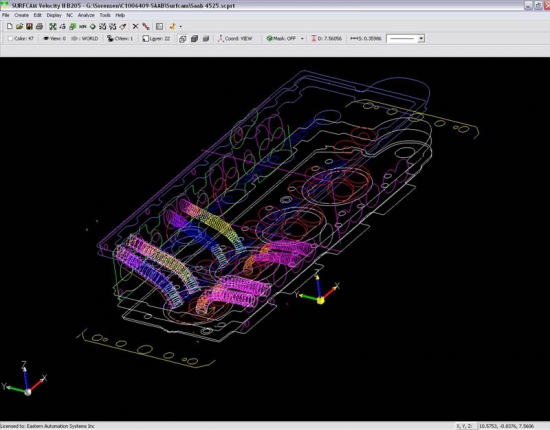

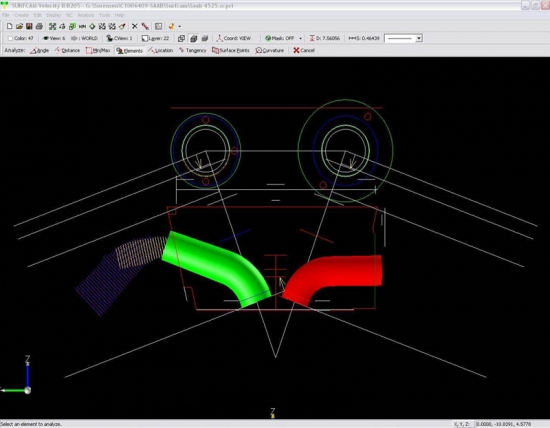

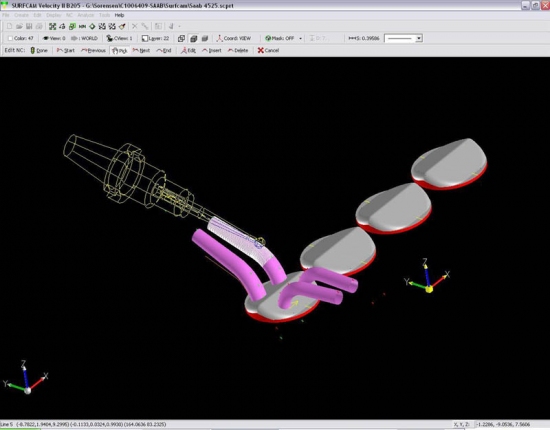

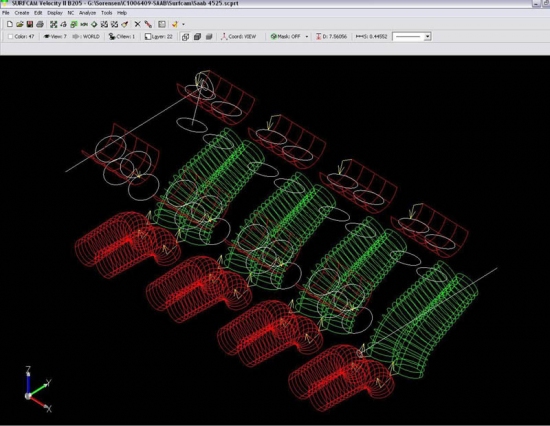

I think you guys will like this :)

Here's some screengrabs of the completed 3D model of the cylinder head. The bare head was digitally scanned and all dimensions from the blueprints overlaid/combined on the model.

You can see in some of the photos there is a cutter present. We were running the tool path simulation to watch how the ports are cut, awesome stuff.

Here's some screengrabs of the completed 3D model of the cylinder head. The bare head was digitally scanned and all dimensions from the blueprints overlaid/combined on the model.

You can see in some of the photos there is a cutter present. We were running the tool path simulation to watch how the ports are cut, awesome stuff.

Re: 16 valve B motor - living the dream

Yes it's really a aresome projekt, CAD/CAM is nice to have stuff!!

Great work...

Great work...

Best regards. Jakob Jensen - Denmark

Building a 99 hill climb/track racer

Building a 99 hill climb/track racer

Re: 16 valve B motor - living the dream

Krister K wrote:Amazing project, love it!

Thanks for the support guys! I am learning a lot in the process so far and that is one of the most meaningful parts of the project to me. I am documenting every step along the way and its amazing how much a project like this can snowball, with small little things taking way more time than ever anticipated. Yesterday I spent about 4 hours just designing and machining a simple fixture just to hold something for one machining operation that took about 5 minutes once it was ready

- DrewP

- Posts: 2084

- Joined: Wed Dec 26, 2007 8:27 pm

- Nickname: TANK

- Number of Saabs currently owned: 1

- Location: Monrovia, CA

Re: 16 valve B motor - living the dream

Will the machine be able to hold tolerance for the lifter bores, or are you going to have to ream them? I assume they are a standard size?

"Lookin' gooood, Cannonball Run!"

Drew

"Lookin' gooood, Cannonball Run!"

Drew

"You can educate ignorance, but you can't fix stupid."

Re: 16 valve B motor - living the dream

DrewP wrote:Will the machine be able to hold tolerance for the lifter bores, or are you going to have to ream them? I assume they are a standard size?

"Lookin' gooood, Cannonball Run!"

Drew

Good question Drew, they are 32mm which is a somewhat odd size I've found, 1 mm smaller than std SAAB 16V @ 33 (also what a lot of BMW's use) . Luckily the lifters came with the kit and they are in great shape. The idea is to cut them as close as possible but just a smidge on tight side and ream/hone them out to final size as needed.

Return to “Projects and Build Threads”

Who is online

Users browsing this forum: No registered users and 2 guests